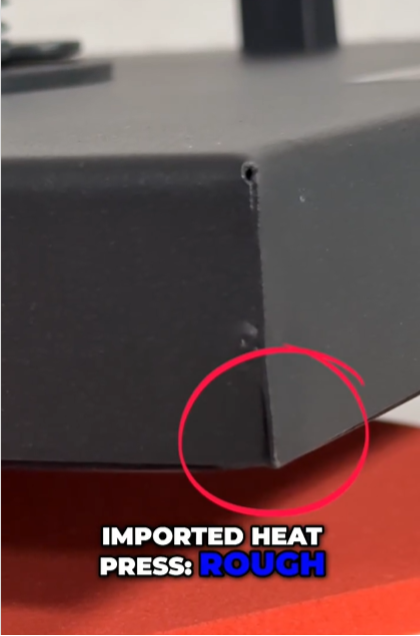

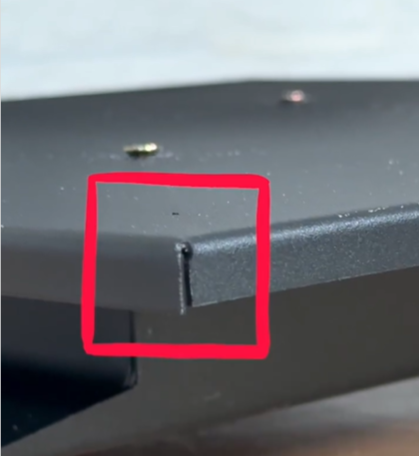

Rough edges on your heat press are like a warning light on your dashboard. You can ignore it for a while, but you won’t like what happens next. Poor finishing is often the result of rushed manufacturing, subpar materials, and minimal quality control. If the manufacturer didn’t take the time to smooth the exterior, what does that say about the care taken with internal wiring, temperature calibration, or pressure alignment?

The Safety Hazard You Can’t Ignore

Rough metal seams and protruding edges can cause cuts or scrapes for anyone operating the press. Even worse, cheap plastic coverings can crack or chip, creating jagged edges over time. In a busy production setting, where speed matters, these hazards can quickly lead to workplace injuries. A press should protect your team, not put them at risk.

Hidden Costs of Cheap Finishing

A snag on a garment or vinyl during application can mean a ruined piece and wasted materials, time, and money. These “small” damages add up quickly, cutting into your profit margins. And when parts wear down prematurely due to poor fit and finish, repairs or replacements become inevitable, wiping out any savings from buying the press in the first place.

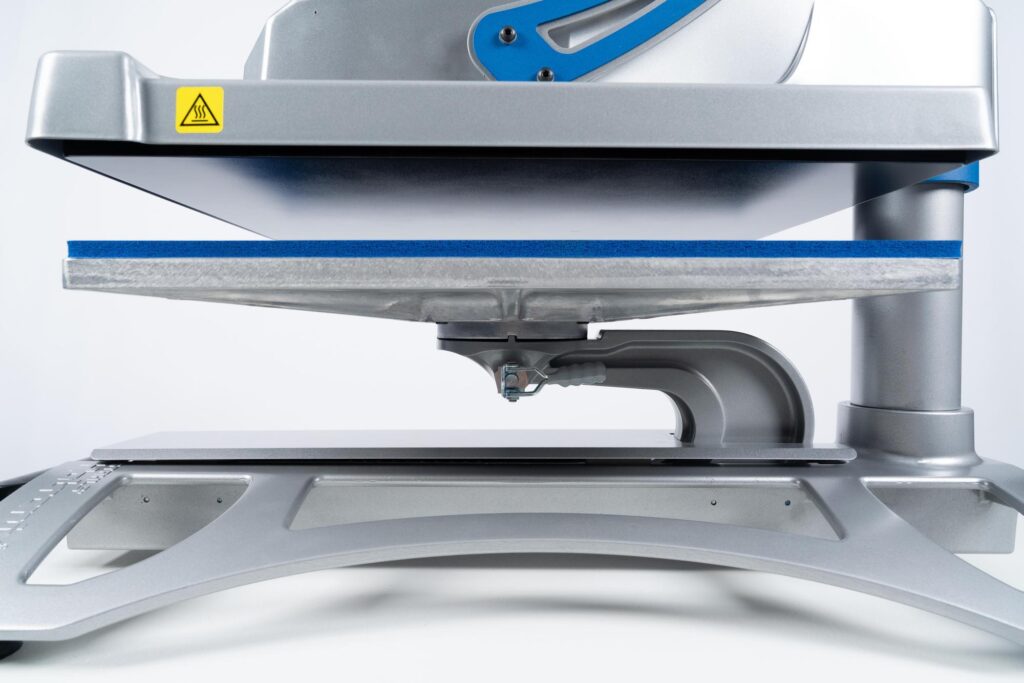

Built for Longevity, Not Shortcuts

Every Hotronix® heat press is crafted with precision engineering and rigorous finishing standards. Edges are smooth and ergonomic, components fit together seamlessly, and every press is tested to ensure safe, consistent operation. By investing in a machine that’s built right from the start, you protect your team, your products, and your bottom line.