Do you realize just how crucial pressure is in heat printing? When transfers won’t stick, edges start lifting, or results come out uneven, it’s almost always due to one thing: uneven or incorrect pressure.

No matter how great your artwork is, or how high-quality your garment may be, without even, consistent pressure across the entire platen, your heat press is setting you up to fail. The kicker? This is exactly where most cheap, imported heat presses fall short.

Warped Platens Lead to Warped Results

Budget heat presses are often made with low-grade metal and thin platens that can’t stand up to the daily demands of professional printing. Over time, repeated use and high temperatures can cause the upper platen to warp or bend slightly, which leads to uneven pressure across the surface.

This causes some parts of your design to receive less pressure than others. As a result, you might see:

- Incomplete adhesion

- Edge lifting

- Uneven finishes

- Failed applications

Even if the transfer looks fine at first, uneven pressure affects long-term durability. That “finished” garment may begin to peel or crack after just one wash, leading to disappointed customers and damage to your brand’s reputation.

Poor Pressure Hurts Your Business

When your press doesn’t perform, it’s not just materials you’re wasting. You also risk losing customer trust. If a customer comes back with a peeling transfer, you may need to reprint the item or issue a refund. Worse, they might choose not to work with you again.

What seems like a bargain when buying a cheap press can end up costing more in the long run through redoing jobs, replacing materials, and repairing your reputation.

A Quick Way to Test Pressure

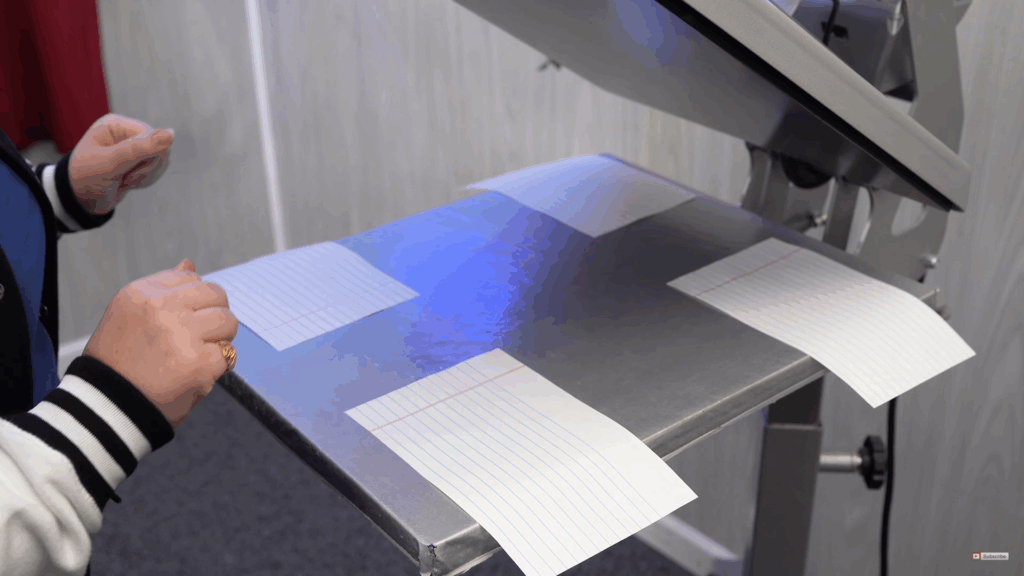

If you suspect your press isn’t applying even pressure, try this simple test:

- Place a piece of paper in each corner of the lower platen.

- Close the press as you normally would.

- Try pulling each piece of paper out.

If one paper slides out more easily than the others, your platen may be warped or uneven. This is common with lower-quality, imported presses that lack structural integrity.

Why It Pays to Invest in Quality

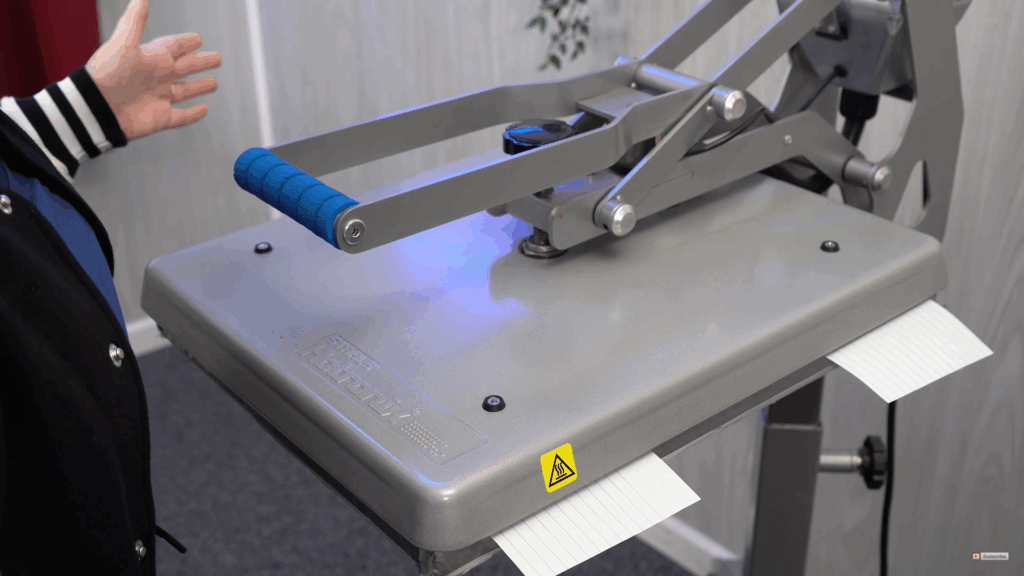

Heat presses like those from Hotronix® are built with precision-engineered, high-quality steel platens that stay flat over time. These presses are designed to apply even, reliable pressure across the entire surface, helping you avoid failed applications and wasted materials.

With a Hotronix press, you can count on:

- Consistent adhesion

- Cleaner results

- Fewer mistakes

- Better customer satisfaction

Don’t Let Cheap Steel Cost You More

Stay tuned for the next post in our 10 Reasons to Think Twice Before Buying a Cheap Import Heat Press series — and in the meantime, learn why poor heat retention is another hidden cost you can’t afford to ignore.

Serious about quality? Don’t let warped platens and flimsy steel hurt your business. Invest in a USA-made heat press for confidence, consistency, and long-term reliability. Explore high-performance Hotronix® heat presses below.