The best way to predict the future is to invent it. – AC Stahl

STAHLS’ SF1 innovation lab officially opened its doors, welcoming clients, decorators, and industry partners to experience firsthand the technologies and strategies shaping the future of branded merchandise. The majority of Fulfill Engine fulfillment will still funnel through the STAHLS’ trusted decorator network; SF1 will take on a portion of overflow orders but primarily serves as a playground for innovation. The entire building is a space to co-create with customers, test new solutions, showcase the next generation of apparel and promotional decoration, and meet with clients in a state of the art showroom.

STAHLS’ Leadership Vision

The event opened with a ribbon cutting ceremony and presentation from STAHLS’ leadership. Both Carleen Gray and Josh Ellsworth addressed the crowd of over 100 decorators, suppliers, equipment manufacturers, industry contacts, and media members, emphasizing a new model for doing business. The future of the industry begins with a shift from prediction to responsiveness, where success comes from connecting with customers and adapting to demand, rather than simply forecasting trends.

The core messaging of the future of branded merchandise centered around these three pillars:

- Sustainability – producing only what people want and reducing waste.

- Innovation – creating products that people actually want to wear and share.

- Scalability – repeatable, flexible production, from one piece to one thousand.

Collaboration and co-creation were also central themes for the day, with a clear focus on the value to be gained with transparency and trust. 1+1 doesn’t equal 2 anymore. With the right partnerships and connections, 1+1 can equal 3, where everyone wins and are more powerful together. Attendees were able to connect and network at multiple points throughout the day, paired with some hands-on experience with a tour of each SF1 decoration station.

Technology in Action: STAHLS’ SF1 Decoration Stations

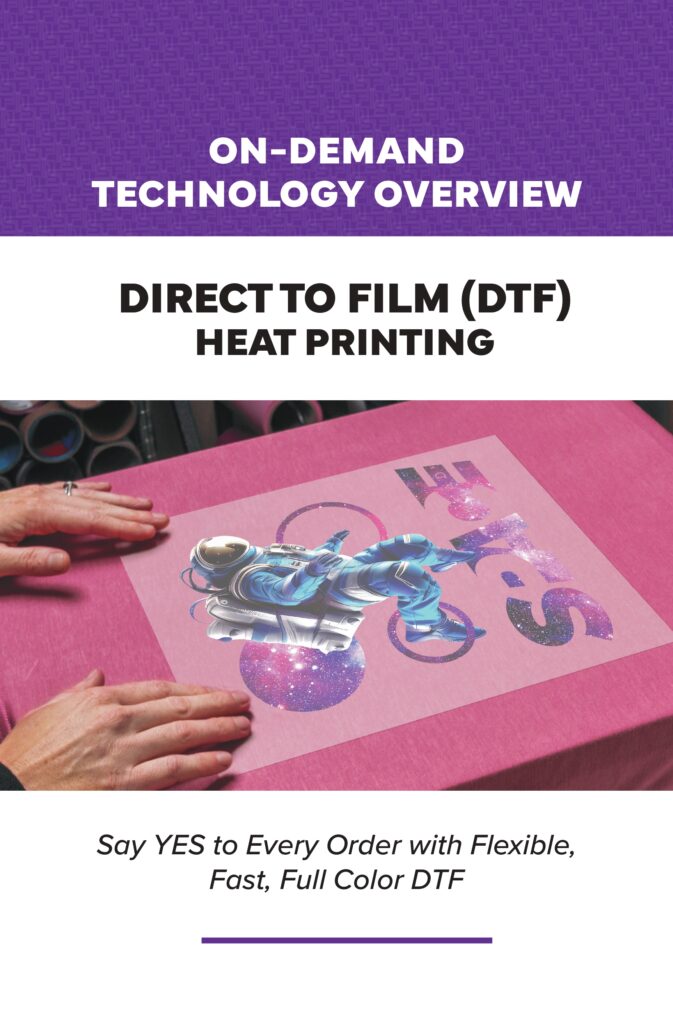

Direct to Film (DTF) Heat Printing

The DTF station highlighted its versatility across fabrics and designs, handling short runs and one-off orders with consistent precision. Visitors could see how DTF opens opportunities for expanding product assortments and executing complex graphics reliably, whether the quantity is one or one thousand.

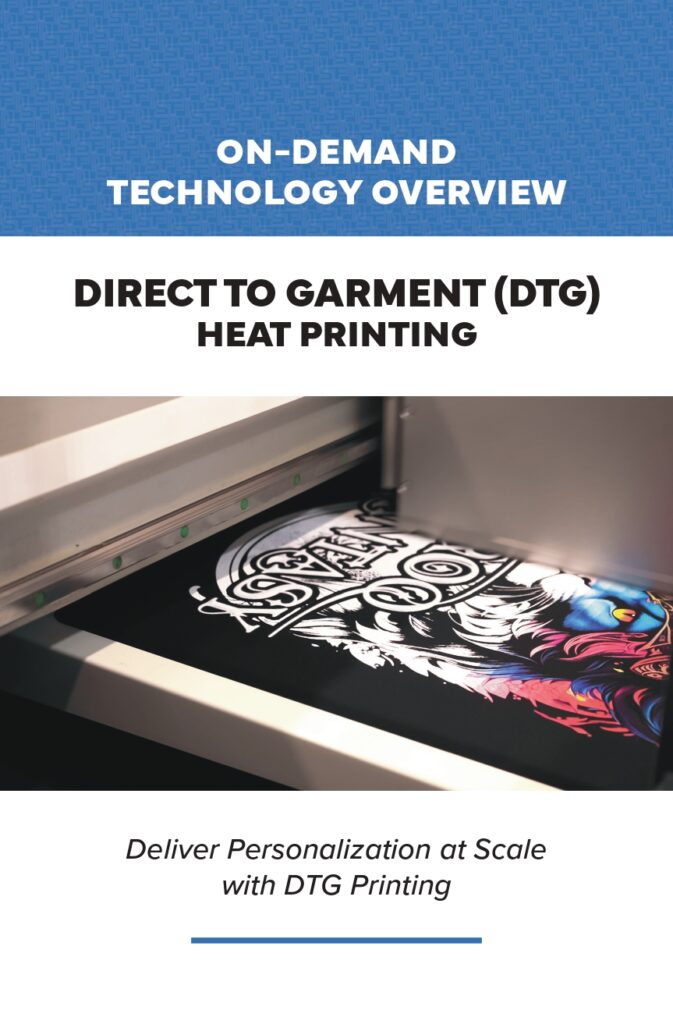

Direct to Garment (DTG) Printing

Visitors observed DTG in action, capable of producing up to 250 shirts per hour. The demonstration showcased how this print technology enables personalization at scale, efficiently handling high-volume orders without sacrificing quality and staying consistent across multiple runs.

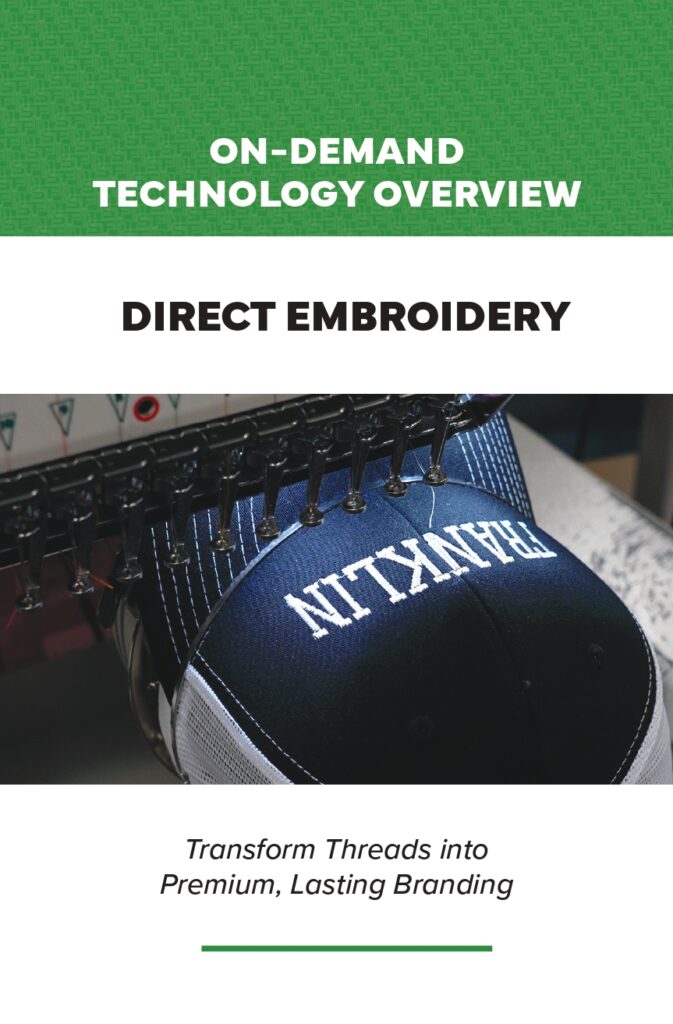

Direct Embroidery

The embroidery station was hands-on, with attendees watching the latest hooping technology from STAHLS’ SF1 in action. The demonstration emphasized how embroidery “doesn’t have to be scary”. Fulfillment through SF1 enables businesses to offer embroidery without investing in expensive equipment. More decorators can create premium, lasting designs at scale, ideal for markets like uniforms, team gear, and corporate merchandise.

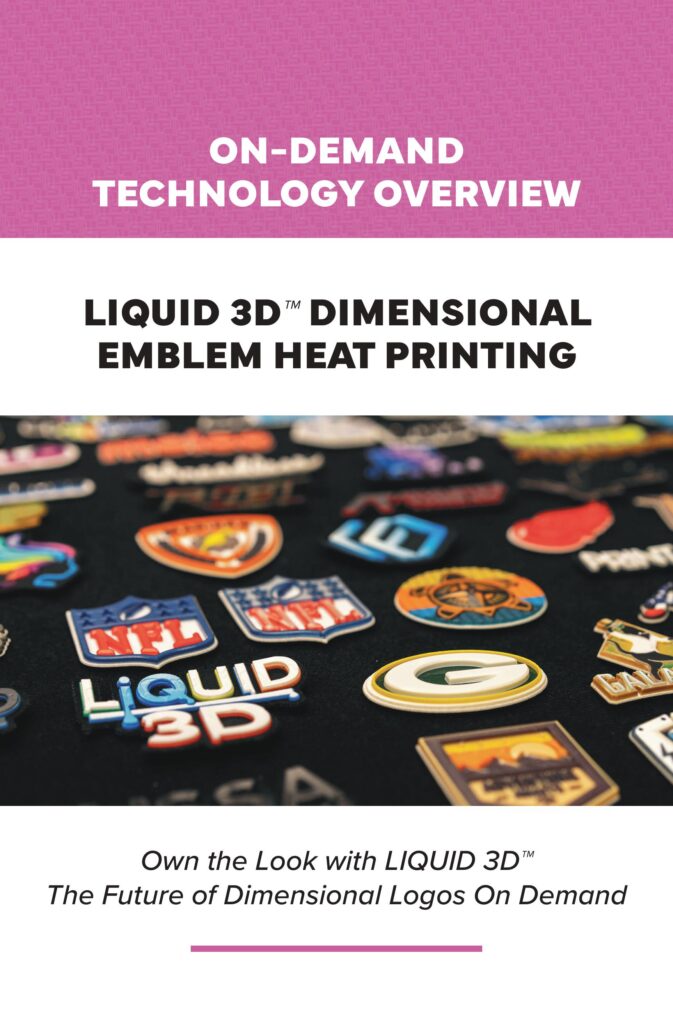

LIQUID 3D™ Dimensional Heat Applied Emblems

The LIQUID 3D™ station was a popular stop for attendees. This brand new, patented dimensional decoration method is capable of producing dimensional logos on demand, in quantities as little as one, shipped in 5 days or less. LIQUID 3D™ gives decorators a chance to tap into the hot headwear market and stand out with a distinctive, premium, and exclusive finish. This station was hopping!

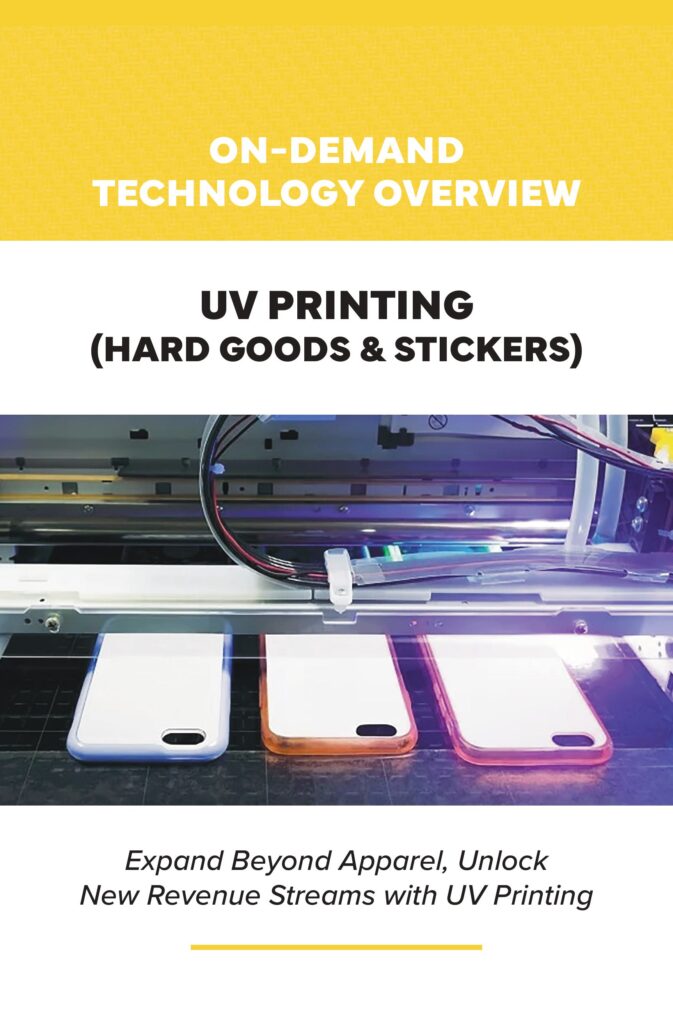

UV Printing (Hard Goods & Stickers)

The UV printing station demonstrated full-color printing on a wide range of hard substrates, including drinkware, wood signs, stickers, and posters. This station highlighted how decorators can expand beyond apparel and offer highly customizable products of nearly any shape or size.

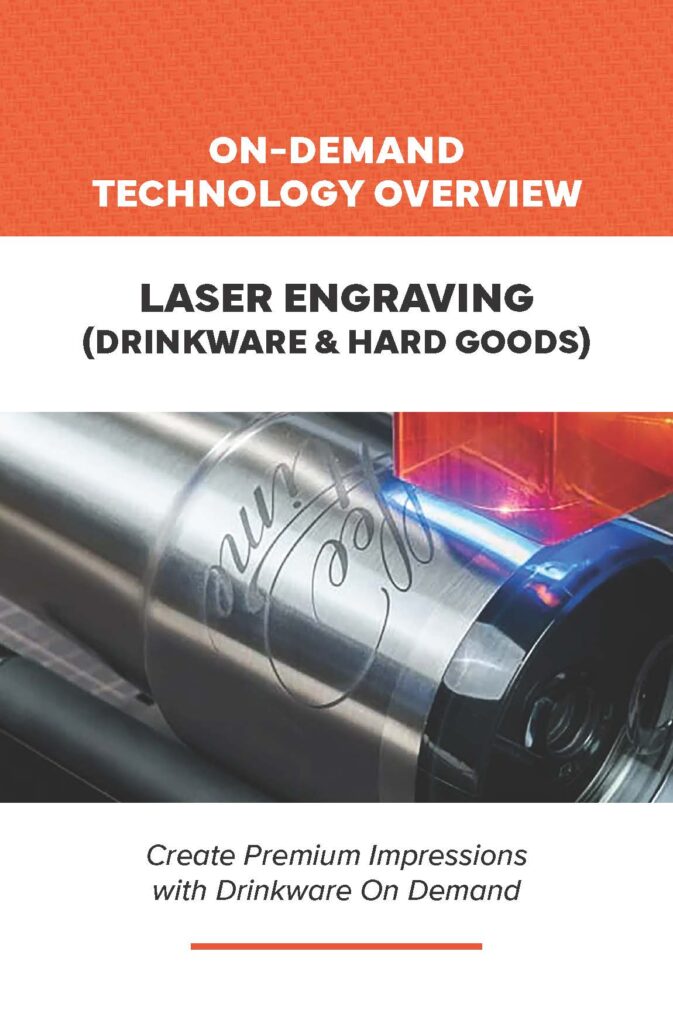

Laser Engraving

The Laser Engraving station displayed permanent, etched finishes on metal drinkware, flasks, padfolios, and more. Visitors at this station gain insight into how to gain more opportunities for premium gifting, recognition items, and repeat event orders. Laser Engraving is a great way to build relationships with brands, corporate buyers, and enter more markets outside of apparel.

Shaping the Future of Branded Merchandise at SF1

SF1 isn’t just a decorating fulfillment center. SF1 is a technology lab, a living showcase of innovation, collaboration, and opportunity. From advanced heat transfers to precision engraving, the grand opening attendees got to see, touch, and experience the technologies that are shaping the future of branded merchandise. The event captured the excitement, creativity, and possibilities SF1 offers to decorators, brands, and the industry as a whole. SF1 brings new ideas to life as a place where people, technology, and collaboration converge to elevate brands, create new things, and meet the growing demands of the ever-evolving decorated apparel industry.