Made a heat Press oops? Don’t panic! It happens to every decorator eventually—you accidentally applied your transfer upside down, and now it’s stuck to the upper platen. The good news? It’s fixable. Just follow these quick steps to get your heat press clean and back in action in no time!

What to Do If You Pressed Your Transfer Upside Down

Act Quickly

You’ll want to immediately address the ink on the upper platen and not wait too long before you start cleaning it.

Turn Off the Heat

Wait for your heat press to cool down, but not completely. A little residual heat left over will help you clean it.

Be Gentle

Grab a soft cloth like a leftover T-shirt and a mild, non-abrasive cleaner. Soap and water or a mild cleaning agent like 409 will work. Start to softly scrub the ink on the platen until it’s all removed. If you’re having a hard time getting it off, you can also wrap a rubber spatula with the cloth and use that to help scrape that residual ink off.

Test Before You Press

Before you get back to business, check to make sure everything is scrubbed off completely by pressing a spare T-shirt or cover sheet before you get to your blank apparel. The last thing you want is another ruined T-shirt!

Maintaining Your Heat Press

Emergencies shouldn’t be the only time you take care of your press! Use the following tips as general maintenance to help extend the life of your press. Remember: a quality heat press that delivers accurate time, temperature, and pressure is key to creating high-quality, durable products.

Test the Pressure

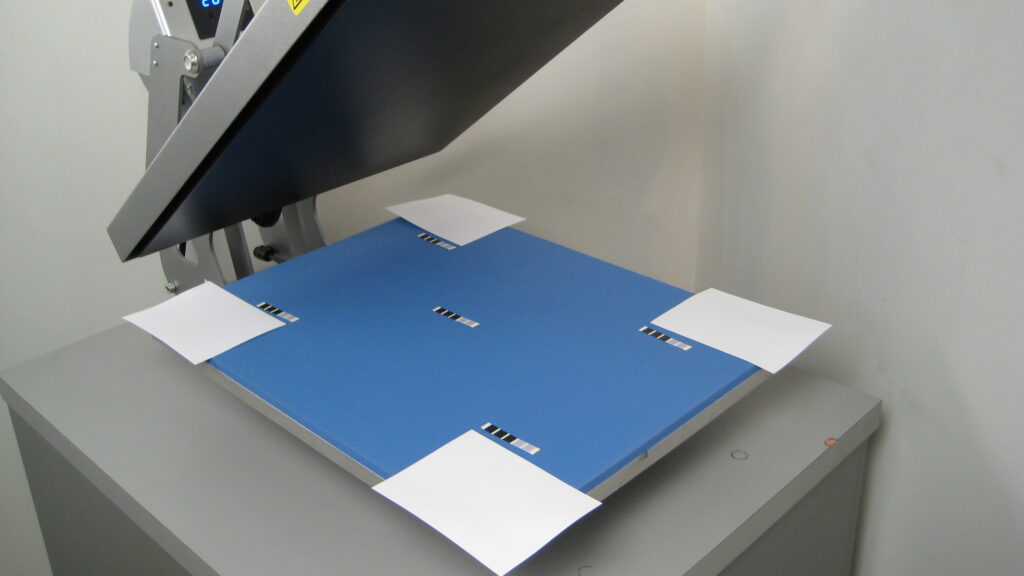

To test the pressure, place a piece of paper at each corner of the lower platen. Lock the lower platen into place, then try to remove the sheets of paper. If any sheets slide out easily, you have uneven pressure.

Clean Upper Platen

Wipe down the upper platen of the heat press machine after each project. Excess ink, adhesives, and other residue can build up and transfer to the next job. Wiping the platen while hot with a clean, dry cloth usually is sufficient.

Check Temperature Accuracy

Make sure the heat press is maintaining heat and is heating evenly throughout the upper platen. Use a heat press test kit to check the accuracy of the temperature.

Cover Lower Platen

Extend the life of the silicone rubber pad on your lower platen with a Quick Slip Lower Platen Protector. Not only does it protect your lower platen from inks and transfers, but it also makes slipping garments on and off of the platen quicker.

Use Dedicated 20 Amp Outlet

To avoid maxing out your electricity or blowing a fuse, we recommend using a dedicated 20-amp outlet for all heat press machines.

Keep a Clean Work Area

Before and after every job, it’s important to clean up your work area. Lint, hair, dust, and other debris can easily be transferred to your substrate when pressing any adhesive-based material.

Use these tips to extend the life of your heat press with regular maintenance and be ready for your next decorating emergency! A clean heat press not only performs better but also protects your transfers, garments, and reputation.